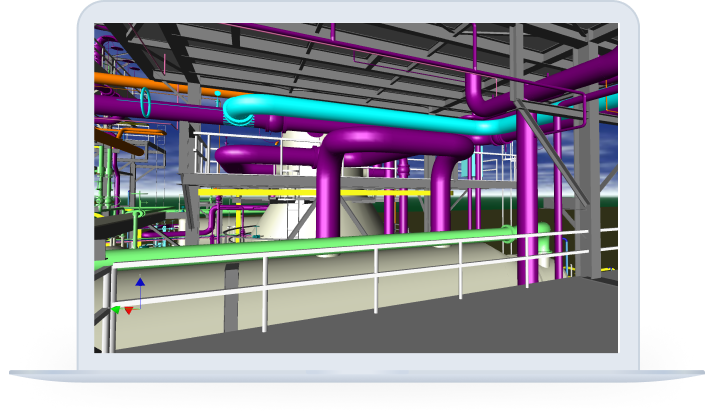

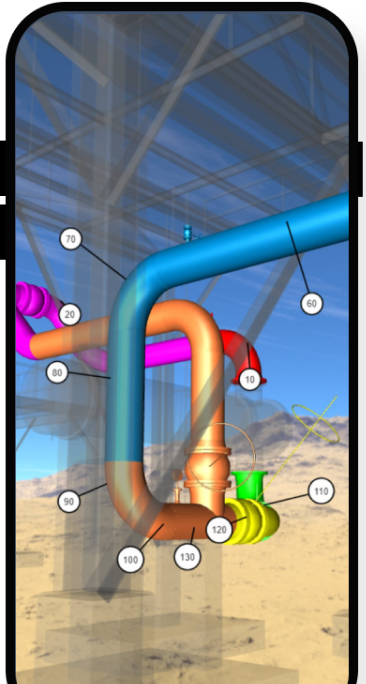

Industrial AI and Digital Twin Technology of Tomorrow - Available Now

Some vendors blow smoke and talk about roadmap visions. Our technology is being leveraged today by teams that are managing some of the largest industrial facilities in the world. Learn how by connecting with a Visionaize product expert.